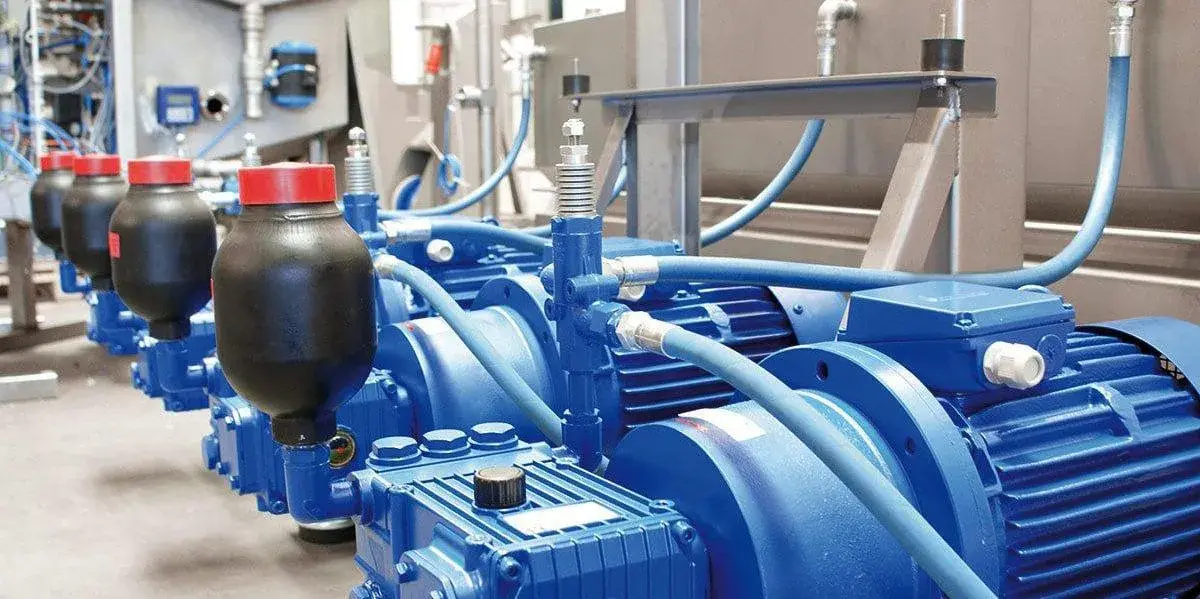

A booster unit, also known as a hydrophore pump, is a system that increases the pressure of the mains water for more efficient cleaning. A booster unit is used in industrial environments where higher pressure (between 20 and 100 bar) is needed for optimal cleaning. Booster units are often used in mobile cleaning systems.

Advantages

Once started up, a booster unit will raise your mains water to the correct working pressure, enabling users to start cleaning. When opening/closing one of the supply points, the unit automatically switches on or goes into standby. The booster unit easy to maintain, emits very little noise and has adjustable feet. The intelligent software makes sure the next pump is started up when needed.

A stainless steel break tank gives the installation certified backflow protection. There is also a dirt trap in the supply line, which ensures that the water supply is free of dirt and breakdowns are prevented. In a multi-pump unit, a flow meter makes sure the next pump starts up or shuts down when needed.

A booster unit is available in several versions and with various additional options. In this way, the booster unit can be adapted to the specific requirements and capacity of your business at any time.

Max. 20 bar working pressure*

For 2 users

Article number: 83301008

Max. 20 bar working pressure*

For 3 users

Article number: 83301009

Max. 20 bar working pressure*

For 4 users

Article number: 83301108

Max. 20 bar working pressure*

For 6 users

Article number: 83301109

Max. 20 bar working pressure*

For 8 users

Article number: 83303004

Max. 20 bar

Max. 12 users

Article number: 83303006

Max. 20 bar

Max. 16 users

Article number: 83303007

Max. 20 bar

Max. 24 users

Article number: 83303015

Max. 40 bar

Max. 3 users

Article number: 83401001

Max. 40 bar

Max. 5 users

Article number: 83401011

Max. 40 bar

Max. 10 users

Article number: 83402001

Max. 40 bar

Max. 16 users

Article number: 83402011

Max. 40 bar

Max. 21 users

Article number: 83402021

Max. 80 bar

Max. 2 users

Max. 2 m3 per hour

Article number: 83501010

Max. 80 bar

Max. 4 users

Max. 4 m3 per hour

Article number: 83501020

Max. 80 bar

Max. 6 users

Max. 6 m3 per hour

Article number: 83501030

Max. 80 bar

Max. 8 users

Max. 8 m3 per hour

Article number: 83501040

Max. 80 bar

Max. 3 users

Max. 3 m3 per hour

Article number: 83502010

Max. 80 bar

Max. 6 users

Max. 6 m3 per hour

Article number: 83502020

Max. 80 bar

Max. 9 users

Max. 9 m3 per hour

Article number: 83502030

Max. 80 bar

Max. 12 users

Max. 12 m3 per hour

Article number: 83502040

An optional stainless steel break tank provides the installation with approved backflow protection.

With a built-in satellite, you can rinse, foam and/or disinfect.

With a built-in satellite, you can rinse, foam and/or disinfect.

Floor-mounted frame for the 60 or 80 bar satellites.

A booster unit is a system designed to raise the water pressure for cleaning purposes in industrial environments.

The most important purpose of a hydrophore pump is to ensure that there is sufficient water pressure available for effective cleaning, regardless of the size of the cleaning project.

A booster unit lets you ensure that you and your colleagues always have sufficient water pressure to clean successfully.

When purchasing an industrial cleaning system, it is crucial to determine how many employees will use it at the same time. This analysis forms the basis for determining the necessary capacity of the booster unit.

Do you want to know more about the necessary capacity of your booster unit? Then click on the button below:

Good hygiene is very important, especially in the food industry. That’s why a booster unit is absolutely ideal for use in the food processing industry.

Booster units are used in this industry to increase the water pressure for cleaning machines, conveyor belts and production areas. This ensures that food products can be processed safely and cleanly.

When it comes to producing and processing food, you obviously don’t want the water pressure to be a problem for any length of time. Fortunately, a booster unit ensures that the water pressure is always satisfactory. So you can rest assured that you’ll always being able to perform your cleaning tasks.

Where you place your booster unit depends on your specific situation. However, we do recommend that you place the unit in a strategic location. In this way, you’ll ensure that the system works effectively and that the water is always at the right pressure.

Some tips for placing your unit in a strategic location:

Booster unit with stainless steel break tank

In many situations, a stainless steel break tank is installed in combination with the booster unit. We recommend you do this to prevent water containing additives used in the cleaning process from flowing back into the mains supply. This tank is usually placed in the vicinity of the booster unit. A stainless steel break tank offers the following advantages:

Want to know more about the advantages of a stainless steel break tank? Find out more in our blog:

Read the blog about the advantages

In brief, a booster unit is a more versatile and complex system that is used for supplying water generally, while a high-pressure pump is specifically designed to supply water at very high pressure for specific tasks.

A booster unit is:

In brief, a booster unit is a more versatile and complex system that is used for supplying water generally, while a high-pressure pump is specifically designed to supply water at very high pressure for specific tasks.

A booster unit is:

The high-pressure systems from Elpress generate a working pressure of at least 60 bar. High-quality Speck plunger pumps are integrated into these systems. These pumps are developed according to the highest standards and with the latest engineering technology. Speck pumps have solid ceramic plungers with a double seal and leakage return.

Unique advantages of a Speck pump:

Do you want a no-obligation discussion about practical provisions that you can implement within your company? Then schedule an appointment with me.