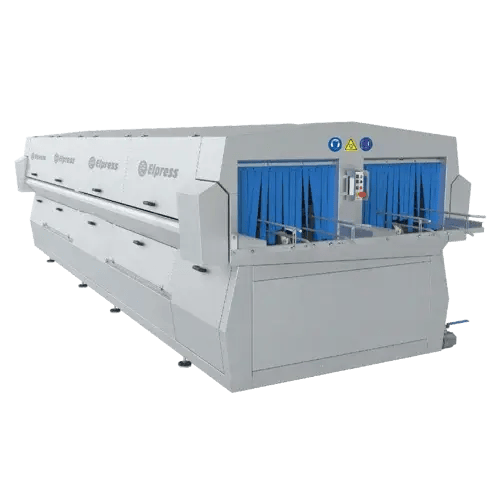

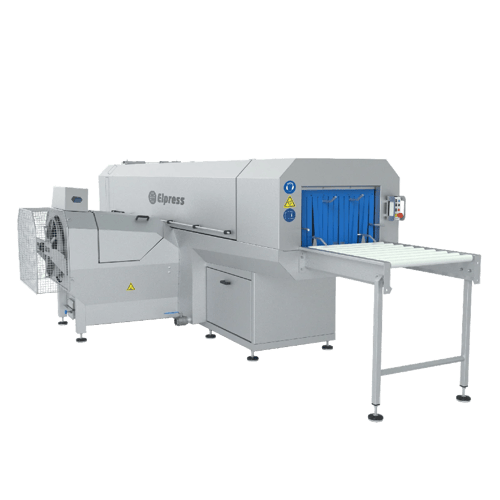

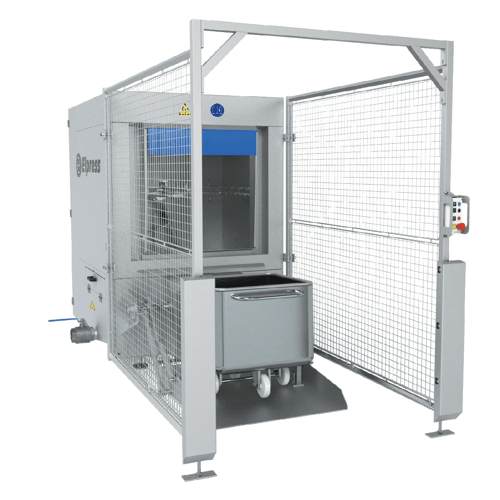

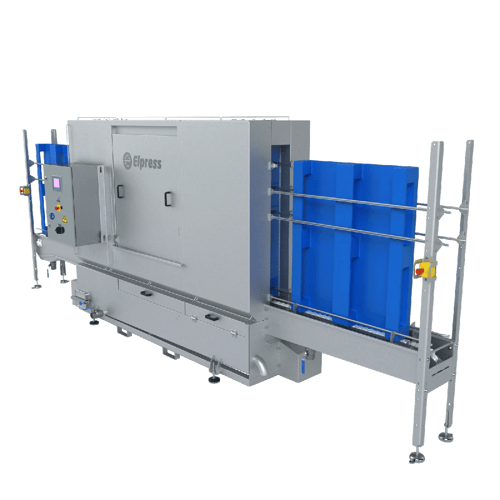

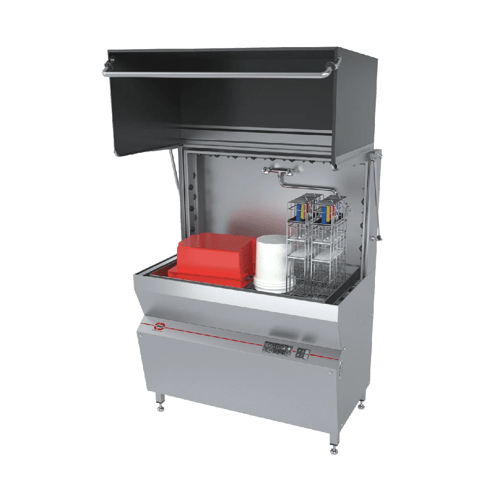

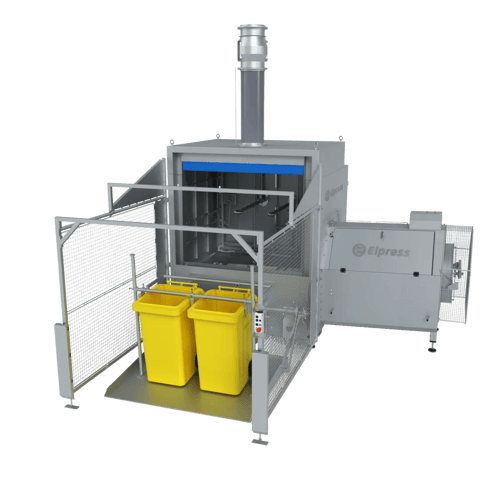

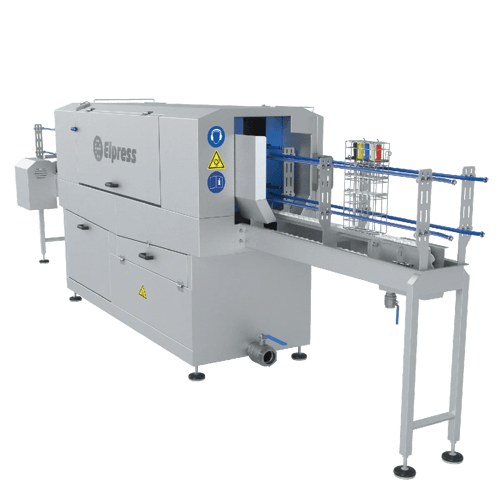

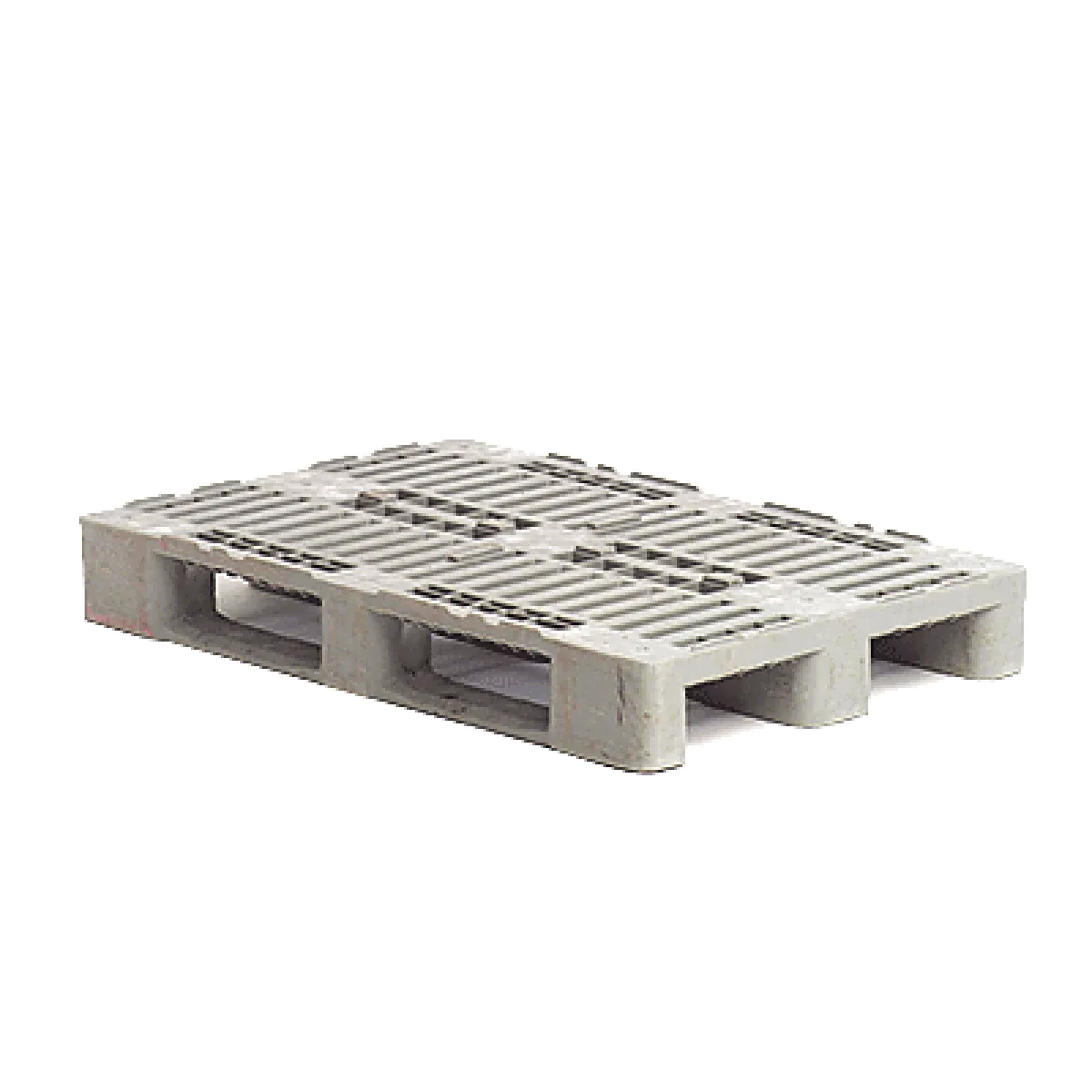

Our industrial washing systems clean load carriers, crates, pallets or boxes. This means dealing efficiently with costs and the environment; our systems are thrifty with water, energy and cleaning agents, without making concessions to the cleaning itself.

Our washing systems utilize a precisely tailored combination of temperature, chemical agents, time, and mechanical force, ensuring optimal cleaning results are always achieved. At Elpress, we are committed to simplifying and optimizing your washing processes. We do this not only by providing suitable, sustainable solutions but also by thinking along with you and offering advice

The benefits of an industrial washing system from Elpress:

Our food-safe washing systems are suitable for use in the meat and fish industry, bakeries, fruits and vegetables (AGF), dairy, confectionery, and logistics organizations. With such an environmentally friendly washing system from Elpress, you can hygienically clean various types of load carriers. The main types of contamination per industry are:

The secret behind the effective eradication of various types of contaminants in just one washing cycle lies in our advanced cleaning philosophy. It approaches the challenge of cleaning through a precise composition of four essential elements: temperature, time, chemistry, and mechanical force. The right alignment of these components enables users of our industrial washing systems to consistently achieve the desired level of hygiene, regardless of the complexity of the contamination. From stubborn proteins and blood residues to challenging fats, sticker and adhesive residues, dried-on contaminants, and even dough - our systems provide a solution that is both thorough and efficient. This not only makes our washing systems versatile but also highly effective in achieving impeccable cleanliness for a wide range of industrial applications.

With an innovative washing system from Elpress, you're not just opting for efficiency and environmental friendliness, but also cost savings. Our certified washing systems are frugal with water, energy, and cleaning agents, without compromising on cleaning machine effectiveness. Thanks to their efficient design and thoughtful elements, resource consumption such as energy and water is minimized. In short, our washing systems are developed with environmental considerations in mind. This is evident in:

Streamlining processes is a top priority for us. Our industrial washing systems are modularly constructed. In the design process, we have considered a wide range of different load carriers. This enables us to often customize our standard washing systems to meet specific customer needs at an attractive investment.

Water and energy are becoming increasingly scarce in the future, and we prioritize efficient use of these resources. By incorporating thoughtful elements, we can continuously reduce consumption without compromising the optimal washing results.

For heating the wash water, there are various options available. The choice depends on the working and operational conditions, with a focus on minimizing energy consumption while ensuring an efficient heating process at Elpress.

Depending on the type of contamination and the used load carriers, we offer the appropriate specific dirt filter. By employing proven and reliable filtering techniques, our industrial washing systems ensure the reuse of wash water.

Do you want a no-obligation discussion about practical provisions that you can implement within your company? Then schedule an appointment with me.