When building the modern slaughter house Elpress were asked to take care of the hygiene facilities. Elpress products can be found in various parts of the slaughter house. The most striking areas are the extensive hygiene stations and a special room for drying boots.

Olivier Reyntjens, Sales Manager Belgium within Elpress, is closely involved with this challenging project. “Such a project with an organisation like Sus (Campiniae) is for me still very special. I have been with Elpress for more than 30 years, but you don’t see projects like this one every day. A lot of time was put into the realisation of this project from both sides, and you can definitely see that. The hygiene solutions tie seamlessly with the rest of the stylish and modern building”, according to Mr. Reyntjens.

In the first part of the hygiene station the employees pass a soap disperser with access control. Only after the employees have used the soap dispenser is access given to the next phase.

In phase two the hands are actually washed. Here the hands are washed with the soap received in phase one, by means of a sensor controlled wash basin. In the same phase the hands are dried. Employees dry their hands by means of sensor controlled Dyson Airblade TAP™ hand dryers. The hands are dried fast, efficiently and hygienically, entirely without contact.

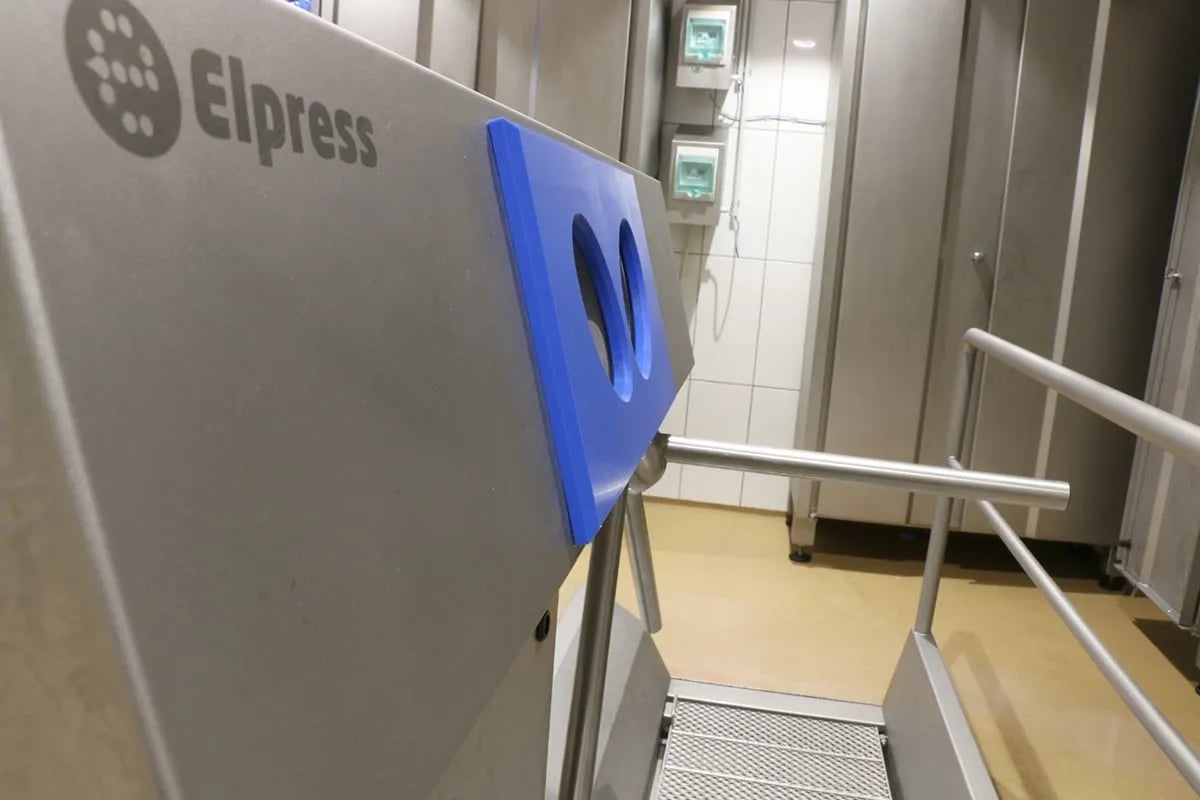

The final step in the hygiene process involves disinfecting the hands and soles. Washing the hands doesn’t remove all bacteria, so that risks remain. Analogous to the first step, during this step access control is also used. Only after taking the disinfectant from the built-in dispenser is the turnstile released, after which employees gain access to the production environment.

Parts 4 and 5 of the sluice (just like the turnstile) are crossed when the employees go through the sluice from the production area into, for example, the canteen. In phase 4 shoe soles are cleansed. As soon as the sensors detect the presence of an employee the brushes start revolving. These sole cleansers have been integrated into the floor so that there are a minimum number of contact points with the floor which prevents bacteria accumulation. This module is available integrated into an extensive hygiene sluice but there are also free standing (smaller) models. Via controlled supplies, water and possibly chemicals are used very efficiently.

Whilst comparable to phase 4, in this step the edges and shafts of the footwear are cleaned to ensure optimal cleansing. As soon as the sensors detect the presence of an employee the brushes start revolving.

In addition to the featured hygiene sluice, Sus Campiniae has, among other things, various pressure booster installations, and a central foam and disinfection installation with tap points. Apron washers and tool washers were also installed in the building in Oevel (Belgium).

Do you want a no-obligation discussion about practical provisions that you can implement within your company? Then schedule an appointment with me.